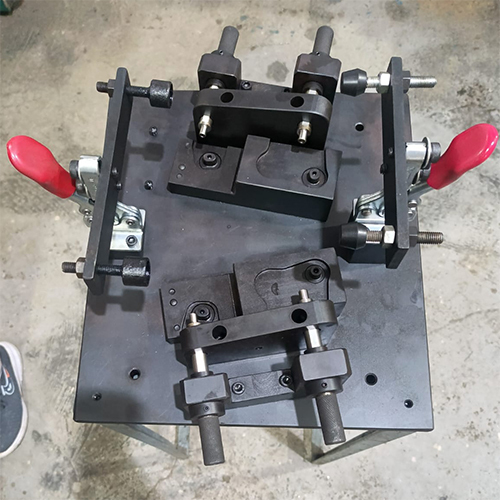

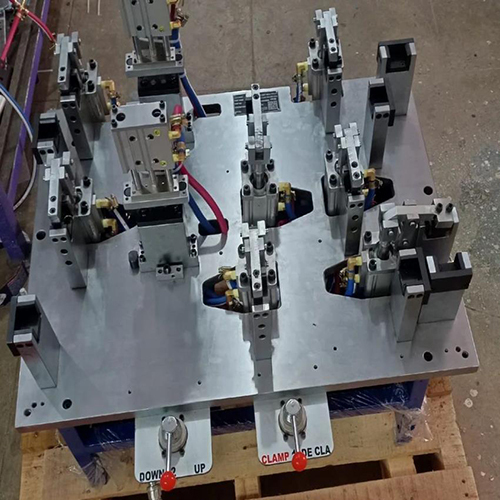

Pneumatic Fixture

Pneumatic Fixture Specification

- Working Process

- Welding

- Usage

- Industrial

- Material

- Mild steel

- Size

- Standard

- Color

- Silver

Pneumatic Fixture Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 2-10 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Pneumatic Fixture

A pneumatic fixture uses compressed air to securely hold and precisely position workpieces during manufacturing processes like machining, assembly, and inspection. Composed of pneumatic actuators, clamps, and sometimes sensors, these fixtures are favored for their speed, repeatability, ease of automation, and ability to provide stable, precise, and efficient operations in industries such as aerospace and automotive.

Key Characteristics and Functions

-

The core function is the use of compressed air to create the clamping force, which makes them powerful yet flexible.

-

They firmly hold and position workpieces, ensuring stability and minimizing movement during processing.

-

Pneumatic fixtures provide accurate and repeatable positioning, which is critical for high-precision operations and minimizing errors.

-

They can be quickly engaged and released, making them ideal for automated, high-volume production environments.

-

They are versatile and can be tailored to suit specific workpieces, shapes, sizes, and clamping requirements.

Components

-

These are the components that use air pressure to drive the clamping mechanisms.

-

Designed to grip the workpiece, providing the necessary hold for operations.

-

May be integrated to monitor the fixture's status, such as whether the pressure frame is closed.

Common Applications

- Machining: Holding parts for drilling, milling, and other precise metalworking operations.

- Assembly: Securing components for joining or fastening processes.

- Inspection: Providing a stable platform for quality control and testing of finished or in-progress parts.

- Welding: Holding parts in the correct alignment for automated welding.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Jig Fixture Category

Receiving Gauge

Price 110000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Size : Standard

Color : Grey

Material : Iron

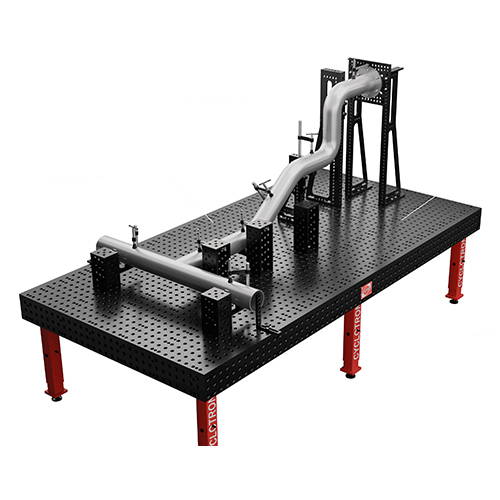

Pipe Welding Fixture

Price 380000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Size : Standard

Color : Black

Material : Other, Mild steel

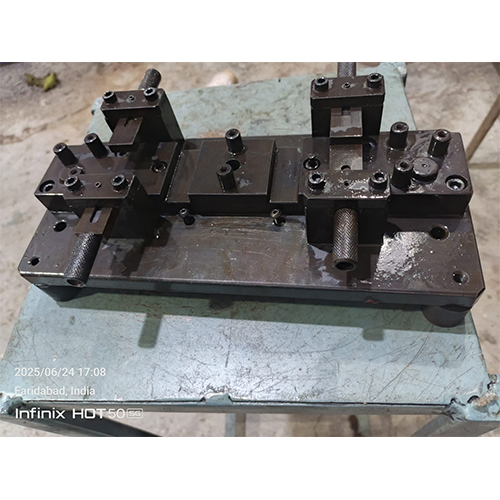

Welding Fixture For Carrier BRKT Process Gauge

Price 125000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Size : Standard

Color : Grey

Material : Iron

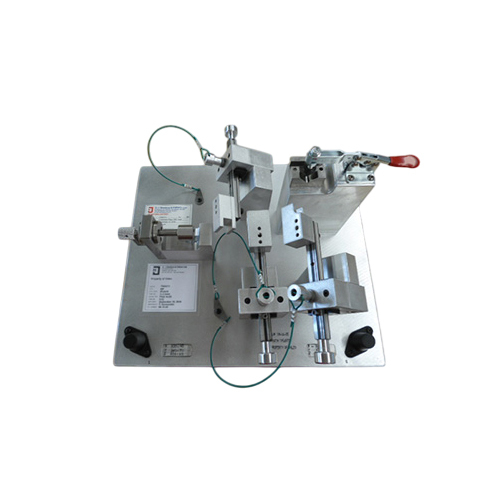

Metal Gauge And Fixture

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Size : Standard

Color : Silver

Material : Other, Mild steel